We guarantee good price of PURE gellan gum with stable and trust-able quality with 10 years.

E418 Gellan gum(also known as Phytagel, Gelzan, Gelrite, or Applied gel are different brand names, they are all essentially the same type of gelling agent, which is Gellan gum) is a multi-functional gelling agent that can produce a wide variety of interesting textures.

CAS:71010-52-1EC:275-117-5HS:39139000

It is extremely effective at low use levels and is available in two forms.

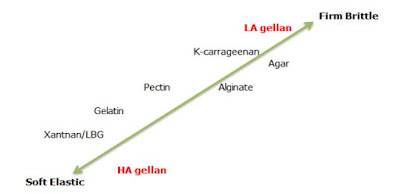

·High Acyl Gellan Gum forms soft,very elastic gels;·Low Acyl Gellan Gum forms firm,brittle gels.

Gellan gum (or E418) is a versatile gelling agent that can produce a wide variety of textures varying from firm, brittle gels that crumble in the mouth, to fluid or elastic gels (depending on conditions & type used). Itcan also be used as a thickening, stabilising and suspending agent. It sets exceptionally fast at ambient temperatures and enables outstanding flavour release.

What is Gellan Gum?

It is derived from Sphingomonas elodea, a bacteria that grows on an aquatic plant.

It forms gels when combined with foods rich in calcium, magnesium or potassium (high positive ion content). Calcium rich dairy products, calcium chloride etc may also be needed to aid setting.

Types of Gellan Gum gel achievable

1. Firm, brittle gel - Using low acyl gellan gum in very low concentrations - from just 0.1% -firm and brittle gels can be made. These gels are crystal clear, making them very appealing visually.

2. Fluid gel - By agitating low acyl gellan gum gels as they cool, fluid gels can be created. They have apparent low viscosity, yet have remarkable suspending properties, successfully suspending particles such as coloured spheres, herbs, and even gases.

3. Elastic gel - By incorporating high acyl gellan, a far more flexible result can be achieved. The resultant gel can be made into thin sheets that can be rolled or folded.

4. Spheres and strands - a pure, gellan gum solution can be dropped into an ion rich water solution to form gelled spheres or strands.

How should Gellan Gum be used?

As well as being heat stable, gellan gum is also stable over a wide pH range meaning it is suitable for use with many different foods. As with any molecular ingredient, experimentation is essential to achieve the desired effect.

Gellan Gum market - By End use

-Food:Beverages,Bakery & Confectionary,Milk & Dairy Products,Sauces & Salad Dressings,.etc-Pharmaceuticals

-Other industries: Oilfield & Gas Industry,Paper Industires,Plant tissue culture engineering,Personal care products,Air Freshener products.etc

Gellan Gum market - By Function

-Thickening,Gelling agent,Stabilizing,Fat Replacer,Emulsification,Preservative.etcHigh Acyl Gellan Gum(E418)

Download COA(PDF)Download TDS(PDF)

Download MSDS(PDF)

CAS:71010-52-1

Group: Emulsifier, Gelling Agent, Hydrocolloid, Stabilizer,Thickener

Other name:pseudomonas elodea gum;Gelrite;Phytagel;gellan gum

Application: Confectionery, Dairy, Flavor & Fragrance, Food, Fruit Preparation, Technical

Origin: Water-soluble Polysaccharide which is produced by the aerobic fermentation of the microorganism Sphingomonas elodea.

Function: Gelling agent and heat stabilizer in fruit preparations, stabilizer in soy drinks and many more.

Qualities:High Acyl Gellan Gum

Packaging and storage:

Net 25 kg per drum(GW:27.5KGS, dia 39CM * H 50CM of drum size)

Store in cool,dry conditions; shelf life of 24months

The following are the detailed technical specifications of high acyl gellan gum

Item | Specification |

High Acyl Gellan Gum | Yellowish powder |

Particle Size(%) | 80mesh≥98 |

Loss on Drying /(%) | ≤15 |

pH(0.5%Solution) | 4.0-7.0 |

Ash(%) | ≤10 |

Lead(Pb)/(mg/kg) | ≤1.0 |

Gellan Gum content(%) | 85-108 |

Suspension Test | Pass |

Aerobic Bacterial Count(CFU/g) | ≤10000 |

Coliforms (MPN/100g) | ≤30 |

Yeast and Mold (CFU/g) | ≤400 |

Salmonella | Not Detected |

Features of Gellan Gum High Acyl:

1.Very low dosage can help to for "fluid gels" to be as suspension or stabilizing agent in beverages:2.Excellent acid stability or wide pH application range:

3.Can help to form elastic gels:

4.Help the blended beverage with a thicker mouth feel:

5.Good combination with modified starch to be used as thickener;

6.Good compatibility with other ingredients and hydrocolloids.

Typical Procedure of Gellan Gum Application:

1. Make gellan gum dispersed in cool deionised water by stirring;2. Heat solution 1. to 80 Celcius Degree;

3. Add cations into solution 2.;

4. Cool down the solution 3. to certain temperatures, stabilizing / suspending functions available.

Dispersion:

To disperse the product without lumps: Premix the powder with the other dry ingredients, and pour the preparation into the liquid under efficient stirring. Continue stirring to obtain a complete dispersion.Dissolution/Hydratioin-how to use high acyl gellan gum:

The dissolution of the product depends on the medium and the process: it is improved by heat treatment (time, temperature), shear stress(stirrer, homogenizer). A complete dissolution can be rapidly obtained by boiling for 5-10min or at around 85-90℃ for 20-30min with sequestrants(Sequestrants such as sodium citrate may be required for hydration in hard water).Typical Applications:

High Acyl Gellan Gum provides fluid gelation, suspension or stabilisation to food and beverage (including dairy products) products.Some Specific Applications:

1. Acid fruit juice;

2. Fruit Pulps Suspending Beverage;

3. Dairy Drinks such as neutral milk, yoghurt, cereal milk, soybean milk, fruits pulps suspending milk beverages;

4. Roughage Drinks;

5. Vegetable protein beverage.

Regulatory Information:

Gellan Gum High Acyl complies with requirements contained in the following regulations and standards: In China: GB25535-2010;In U.S.A.: FOOD CHEMICALS CODEX, 21 CFR § 172.665; In Canada: CANADIAN FOOD AND DRUG LAW (ITEM G.2,TABLE IV), In EU: THE PURITY CRITERIA IN THE CURRENT EC DIRECTIVE, 1829/2003/EC; EU Regulation 2021/1165 Others:JECFA Standard.Low Acyl Gellan Gum(E418)

Download COA(PDF)

Download TDS(PDF)

Download MSDS(PDF)

CAS:71010-52-1

Group: Emulsifier, Gelling Agent, Hydrocolloid, Stabilizer,Thickener

Other name:pseudomonas elodea gum;Gelrite;Phytagel;gellan gum

Application: Confectionery, Dairy, Flavor & Fragrance, Food, Fruit Preparation, Technical

Origin: Water-soluble Polysaccharide which is produced by the aerobic fermentation of the microorganism Sphingomonas elodea.

Function: Gelling agent and heat stabilizer in fruit preparations, stabilizer in soy drinks,plant tissue culture media and many more.

Qualities:Low Acyl Gellan Gum

Packaging and storage:

Net 25 kg per drum(GW:27.5KGS, dia 39CM * H 50CM of drum size)

The following are the detailed technical specifications of Low Acyl Gellan Gum

Items | Index |

Low Acyl Gellan Gum | White powder |

Gellan Gum content(%) | 85.0—108.0 |

Loss on drying(%) | ≤15.0 |

Lead(mg/kg) | ≤1.0 |

Particle size(%) | 60 Mesh ≥95 |

Transparency(%) | ≥85 |

Gel strength(g/c㎡) | ≥1100 |

Ash(%) | ≤15 |

PH(1% Solution) | 4.5—7.0 |

Bacterium account(CFU/g) | ≤10000 |

Coliforms(MPN/100g) | ≤30 |

Yeast and mould(CFU/g) | ≤400 |

Salmonella | Not Detected |

Features of Gellan Gum Low Acyl:

Typical Procedure of Gellan Gum Application:

Dispersion:

Dissolution/Hydratioin-how to use low acyl gellan gum:

Gel Formation:

Typical Applications of Gellan Gum Low Acyl:

Regulatory Information:

·Setting Temperature;·Degree of structure;·Thermal stability;·Low viscosity suspension ability.

Gellan Gum has E number E418 and due to the above outstanding properties it is widely used in many products that require gelling,suspending,stabilizing,texturizing,

Popular field applications such as food, beverage, plant tissue culture,microbiological culture ,cosmetic, oral care,pharmaceutical and also in various industrial applications(air freshener industry Paper industry.etc).

Gellan Gum Origin:

-Gellan is an anionic polysaccharide, which is produced by Sphingomonas paucimobilis bacterium(ATCC31461) through aerobic fermentation. Purified by alcohol precipitation.-In 1978, in CP Kelco Kaneko and Kang found a water soluble polymer – gellan-In 1988, Japan approved gellan gum for use in food products.-In 1992,FDA approved the use of gellan gum as an food additive. It has E-number E418.

Structure:

High Acyl Gellan Gum forms soft,very elastic gels;Low Acyl Gellan Gum forms firm,brittle gels.

Features

-Forming gel ,low dosage(at lest 0.05%) forms gel-Excellent stability(PH ,Heat)-No protein interaction-Fluid gel(suspension)-High clarity-Flexibility in melting and setting temp.

Gel Formation

Dispersion

Poor dispersion will result in incomplete hydration and loss of gum functionality.

Solutions:

-Blending with dispersants such as sugar,sodium citrate etc.-Stirring or starting the agitator before adding.-Using well dispersion products such as KELCOGEL or CINOGEL GELLAN GUM

• Concentration of ions in solution will affect the hydration temp. such as calcium , Sodium

• Low acyl gellan gum requires a temperature of 75 ℃(1670F) to fully hydrate the gum.• High acyl gellan gum hydrates between 70℃ and 80 ℃(1580F and 1760F) even in relatively high ion concentrations

Gel formation

In the absence of added cations, low acyl gellan gum gels set at around 25℃ (770F), where high acyl sets at around 65℃ (1490F). With added calcium or sodium ions,the setting temperature increases.

Gel Texture

• Low acyl –-hard brittle gel• High acyl—soft elastic gel• Blending two types with vary ratios a wide variety of textures can be obtained.• It is possible to obtain textures close to those of carrageenan and gelatin gels.

Comparation to the other hydrocolloids gel

Blends of Low Acyl and High Acyl Gellan Gum

Low acyl gellan gum gels have a firm, brittle texture. Adding a high acyl gellan gum reduces the brittleness.By varying the ratio of these two forms of gellan gum, a wide variety of textures can be obtained.Blends of low acyl and high acyl gellan gum can match the texture of other hydrocolloids.By varying the ratio of low acyl and high acyl gellan gums it is possible to obtain textures close to those of carrageenan and gelatin gels.

Blends with other Hydrocolloids

Other thickening or gelling agents, such as starch, guar gum, locust bean gum, cellulose derivatives or xanthan gum, may also be used with gellan gum in order to obtain the desired texture.

Certain hydro- colloids, when combined with low acyl gellan gum, cause a progressive reduction in the hardness and modulus values of the gellan gum gels. Brittleness remains essentially constant and springiness increases slightly.

Thermo-reversible Gels

In most practical situations, gels made with low acyl gellan gum are not thermally reversible. Most gels of low acyl gellan gum are retort or bake-stable. Gels made with high acyl gellan gum will soften with heating, and will melt with prolonged heating.

The greater the concentration of ions, the higher the melting temperature.

Milk Systems. Gels made with low concentrations of monovalent ions melt easily. For example, in milk systems both high and low acyl gellan gum form thermo-reversible gels as it is believed that in milk, gellan gum sets predominately with potassium rather than calcium ions

Degradation during Gel Preparation

Low acyl gellan gum is very stable. Like other polysaccarides, gellan gum will undergo hydrolytic degradation at high temperature, especially in acidic conditions. However, at pH 3.5, a low acyl gellan gum solution can be maintained at 80°C for up to one hour with minimal deterioration in the quality of the subsequently formed gel.

High acyl gellan gum is more susceptible to degradation so long hold times in acidic conditions should be avoided. For UHT milk process systems, the low acyl form of gellan gum should be used for long term product stability.

The Beneficial Properties of Gellan Gum Fluid Gels

Gellan gum fluid gels are solutions with a weak gel structure. They exhibit an apparent yield stress,i.e., a finite stress which must be exceeded before the system will flow. These systems are very good at suspending particulate matter since, provided the stress exerted by the action of gravity on the particles is less than the yield stress, the suspension will remain stable.

Their highly pseudoplastic flow provides extremely efficient suspension combined with low viscosity at higher rates of shear. This results in low viscosity in the mouth, making them particularly effective in beverages for suspension of fruit pulp or jelly pieces. Suspension can be achieved without adversely affecting the mouthfeel.

Other important properties of gellan gum fluid gels are the setting temperature, degree of structure and thermal stability. All of these properties are, as with normal unsheared gels, dependent upon the concentration of gellan gum and the type and concentration of gelling ions.

Fluid gel formation is employed in the production of dairy products, spreads, dressings, and sauces using scraped surface heat exchangers or during HTST/UHT processing.

Gentle agitation of a weak gellan gum gel, after it has set, is also sufficient to form a smooth, pourable fluid gel. This means that fluid gels can be formed using standard filling operations.

Gellan Gum Typical Application

• Key features※ High gel strength※ High transparent※ Quickly gelling※ Acid & heat stability※ Low syneresis※ Low dosage• Basic formulationWater: 42% Fruit juice: 42%Sugar:15.15% Citric acid: 0.4Sodium citrate:0.30% Gellan Gum:0.15%

• Key features※ Fluid gel※ Low dosage 0.02-0.15%※ Low viscosity※ Prolong shelf life※ Good flavor release• Basic formulationWater : 88.117% Sugar: 11.25%Sodium citrate:0.06% Gellan Gum: 0.028%Sodium benzoate:0.02% Citric acid :0.5%Calcium lactate:0.025%

• Key features※ Excellent stability※ High gel strength※ Sparkling transparent※ Acid & heat stability※ High melting temp.※ Low syneresis• Basic formulationWater: 49.3% Glucose Syrup:45%Gellan Gum:0.5% Carrageenan:2.5%Citric acid:1.3% Sodium citrate:1.3%

• Key features※ Heat stability※ 1/5 agar use levels※ High transparent clear solutions※ Low syneresis※ Quickly gel formation• Basic formulationMS medium solutionGellan Gum: 0.25%Sugar: 3%

• Key features※High gel strength※High Transparent※Thermal irreversible gel※No syneresis• Basic formulationWater: 82.38%Tween-20:1.5%Gellan Gum:0.8%Ethanol: 5%Flavor: 10%Calcium Chloride:0.1%Color:0.02%Sodium benzoate:0.2%

• Key features※ Low hydration temp※ No syneresis※ Low protein interaction※ Acid stability※ Prolong shelf life• Basic formulationSkim milk : 90%Sugar: 6.8%Gellan Gum: 0.05%Pectin:0.15%Strain:3 %

• Key features※ No syneresis※ Acid stability※ Fluid gel※ Low viscosity※ Low dosage 0.025—0.15%• Basic formulationMango &orange juices: 99.85%Gellan Gum 0.12%Citric acid: 0.03%

• Key features※ Pseudoplastic fluid※ Control syneresis※ High transparent※ Excellent flavor release※ Excellent stand-up• Basic formulationSodiumPhytate:0.2%Sodium Fluoride:0.3%Sorbitol :30%Sodium Saccharinat:0.2%Glycerin :20%Cellulose Gum :0.2%

Flow chart of Gellan Gum