Gellan Gum Origin:

- Gellan is an anionic polysaccharide, which is produced by Sphingomonas paucimobilis bacterium(ATCC31461) through aerobic fermentation. Purified by alcohol precipitation.

- In 1978, in CP Kelco Kaneko and Kang found a water soluble polymer – gellan

- In 1988, Japan approved gellan gum for use in food products.

- In 1992,FDA approved the use of gellan gum as an food additive. It has E-number E 418.

Structure:

CINOGEL BIOTECH,a professional gellan gum manufacturer & supplier in China which foucs on both high acyl & low acyl gellan gum with production of 500MT per Year;

The gellan gum we produced are 100% pure & natural & NON-GMO;

The gellan gum we produced are 100% pure & natural & NON-GMO;

It is extremely effective at low use levels and is available in two forms.

- High Acyl Gellan Gum forms soft,very elastic gels;

- Low Acyl Gellan Gum forms firm,brittle gels.

Features

- Forming gel ,low dosage(at lest 0.05%) forms gel

- Excellent stability(PH ,Heat)

- No protein interaction

- Fluid gel(suspension)

- High clarity

- Flexibility in melting and setting temp.

Gel Formation

Dispersion

- Poor dispersion will result in incomplete hydration and loss of gum functionality.

Solutions:

- Blending with dispersants such as sugar,sodium citrate etc.

- Stirring or starting the agitator before adding.

- Using well dispersion products such as KELCOGEL or CINOGEL GELLAN

Hydration:

solution will affect the

hydration temp. such as

calcium , Sodium

• Low acyl gellan gum

requires a temperature of

75 ℃(1670F) to fully

hydrate the gum.

• High acyl gellan gum

hydrates between 70℃ and

80 ℃(1580F and 1760F)

even in relatively high ion

concentrations

Gel formation

In the absence of added

cations, low acyl gellan

gum gels set at around

25℃ (770F), where high

acyl sets at around 65

℃ (1490F). With added

calcium or sodium ions,

the setting temperature

increases.

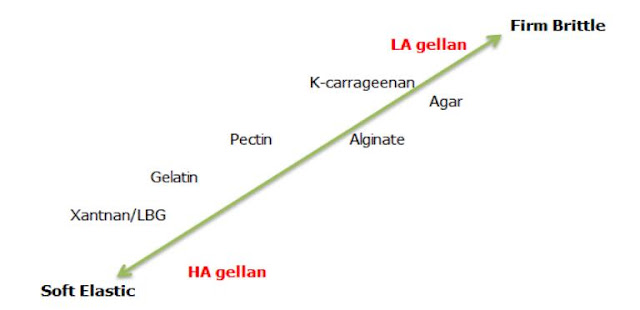

Gel Texture

• Low acyl –-hard brittle gel

• High acyl—soft elastic gel

• Blending two types with

vary ratios a wide variety

of textures can be obtained.

• It is possible to obtain

textures close to those of

carrageenan and gelatin gels

Comparation to the other hydrocolloids gel

Gellan Gum Typical Application

Dessert jellies

• Key features

※ High gel strength

※ High transparent

※ Quickly gelling

※ Acid & heat stability

※ Low syneresis

※ Low dosage

• Basic formulation

Water: 42% Fruit juice: 42%

Sugar:15.15% Citric acid: 0.4

Sodium citrate:0.30% Gellan Gum:0.15%

Suspension drinks

• Key features

※ Fluid gel

※ Low dosage 0.02-0.15%

※ Low viscosity

※ Prolong shelf life

※ Good flavor release

• Basic formulation

Water : 88.117% Sugar: 11.25%

Sodium citrate:0.06% Gellan Gum: 0.028%

Sodium benzoate:0.02% Citric acid :0.5%

Calcium lactate:0.025%

※ Fluid gel

※ Low dosage 0.02-0.15%

※ Low viscosity

※ Prolong shelf life

※ Good flavor release

• Basic formulation

Water : 88.117% Sugar: 11.25%

Sodium citrate:0.06% Gellan Gum: 0.028%

Sodium benzoate:0.02% Citric acid :0.5%

Calcium lactate:0.025%

Confectionery

• Key features

※ Excellent stability

※ High gel strength

※ Sparkling transparent

※ Acid & heat stability

※ High melting temp.

※ Low syneresis

• Basic formulation

Water: 49.3% Glucose Syrup:45%

Gellan Gum:0.5% Carrageenan:2.5%

Citric acid:1.3% Sodium citrate:1.3%

Plant Tissue Culture Study

• Key features

※ Heat stability

※ High transparent

※ Low syneresis

※ Quickly gel formation

• Basic formulation

MS medium solution

Gellan Gum: 0.25%

Sugar: 3%

Air Freshener Gel

• Key features

※High gel strength

※High Transparent

※Thermal irreversible gel

※No syneresis

• Basic formulation

Water: 82.38% Tween-20:1.5%

Gellan Gum:0.8% Ethanol: 5%

Flavor: 10% Calcium Chloride:0.1%

Color:0.02% Sodium benzoate:0.2%

Yoghurt

• Key features

※ Low hydration temp

※ No syneresis

※ Low protein interaction

※ Acid stability

※ Prolong shelf life

• Basic formulation

Skim milk : 90% Sugar: 6.8%

Gellan Gum: 0.05% Pectin:0.15%

Strain:3 %

Fruit Juice Beverage

• Key features

※ No syneresis

※ Acid stability

※ Fluid gel

※ Low viscosity

※ Low dosage 0.025—0.15%

• Basic formulation

Mango &orange juices: 99.85%

Gellan Gum 0.12%

Citric acid: 0.03%

Toothpaste and personal care products

• Key features

※ Pseudoplastic fluid

※ Control syneresis

※ High transparent

※ Excellent flavor release

※ Excellent stand-up

• Basic formulation

SodiumPhytate:0.2%

Sodium Fluoride:0.3%

Sodium Fluoride:0.3%

Sorbitol :30%

Sodium Saccharinat:0.2%

Sodium Saccharinat:0.2%

Glycerin :20%

Cellulose Gum :0.2%

Cellulose Gum :0.2%

XanthanGum:0.2%

Gellan Gum :0.05%

Gellan Gum :0.05%

Titanium Dioxide: 1% ,

Hydrated Silica: 15%

Hydrated Silica: 15%

Aroma: 1% ,Citric Acid :0.5% ,Water:31.35%

And Many More Applications in Pharmaceutical Uses: Gellan Gum can be used to produce easy- to - swallow solid dosage forms,such as gels and cotaed tablets, and to modify the rate of release of active ingredients from tablets and capsules.